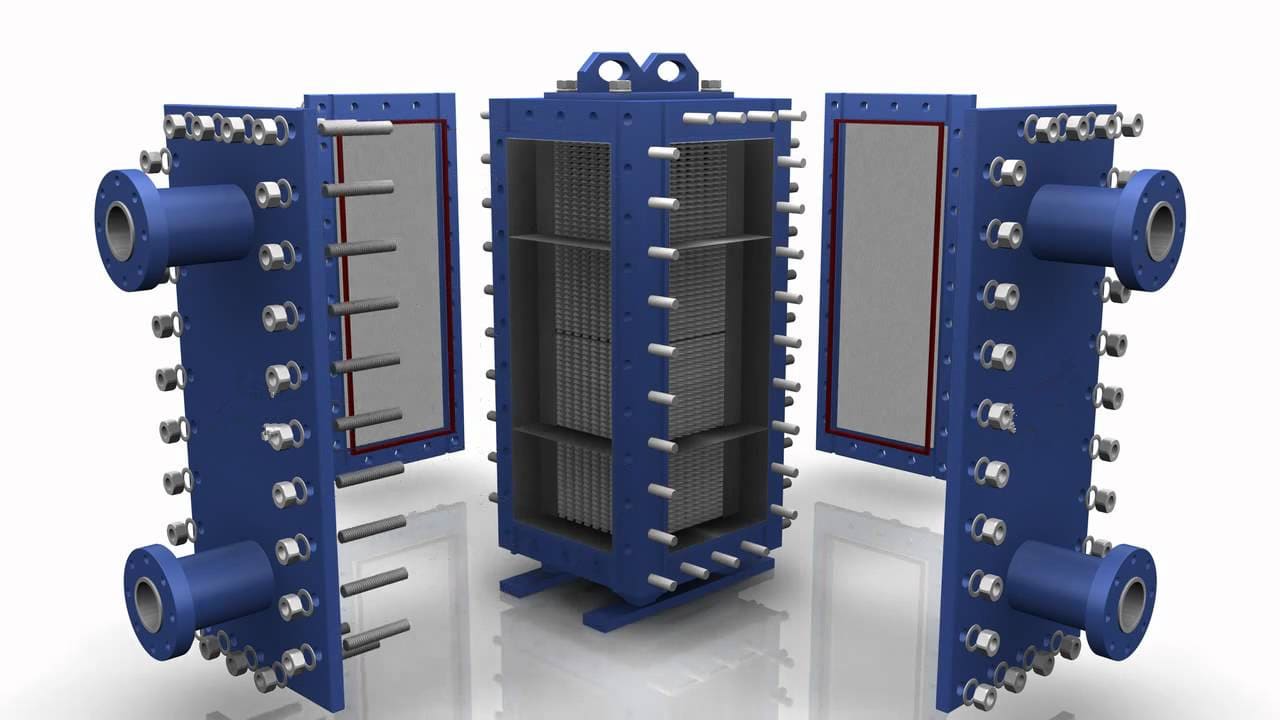

Fully-Welded Plate Heat Exchangers

Plate to Plate Heat Exchanger

GRANO welded plate type heat exchanger can be opened at both sides and designed without any seal gaskets installed between heat transfer plates, it can provide large heat transfer area within a compact space, and can be opened at two sides for cleaning.

The fully-welded plate heat exchanger is designed that the heat transfer plates, frame columns and cover panels are bolted into a plate bank assembly, this assembly is bolted with the rigid rectangle-shaped side panels to form a unit. Sealing strips (gaskets) are installed between the plate bank and side panels (4 gaskets are required for each heat exchanger). Side panels are served to separate the fluid loop and enhance mechanical strength, and removable baffles can be installed for each fluid loop.

GRANO fully-welded plate heat exchangers make a convincing case due to their minimal size, outstanding heat transfer coefficients and comparatively minimal investment costs. They are particularly robust and require only minimal cleaning and servicing. The design advantages thus come into play in areas in which in addition to the output, load capacity is also required. In addition, each series has its specific advantages and areas of application.

GRANO Fully Welded Plate Heat Exchangers are widely applied in the oil and gas industry, refinery applications, pharmaceutical industry, chemical/petrochemical industry, automotive, pulp and paper industry and steel industry.

The conclusion: Developed for the challenges of specific applications, our fully-welded plate heat exchangers offer convincing performance even under the most difficult circumstances.