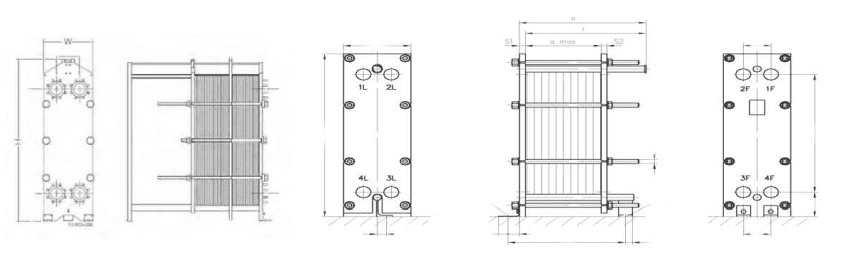

Gasketed Plate Heat Exchanger

Gasketed Heat Exchanger

A plate heat exchanger (PHE) comprises a pack of spaced corrugated plates arranged such that the two heat exchanging fluids flow through alternate spaces in the pack. The corrugations maintain the gap between adjacent plates which are sealed against each other. These are nowadays several different technologies to effect a seal between the plates and to maintain the pack in a compressed state.

Normally plates are pressed and expensive tools are required for their production. Unlike shell and tube units, plates are produced in a limited number of sizes and are never custom made to individual requirements. However, the flexibility of their arrangement enables a particular duty to be easily handled by the correct selection of standard components.

The plate heat exchanger is the most advanced energy-efficient heat transfer equipment.

What are the advantages of Gasketed Plate Heat Exchanger?

- High heat transfer efficiency

- Low pressure lose

- Compact structure

- Easy assembly & disassembly

- Sensitive temperature control

- High operating flexibility

- Long life-time